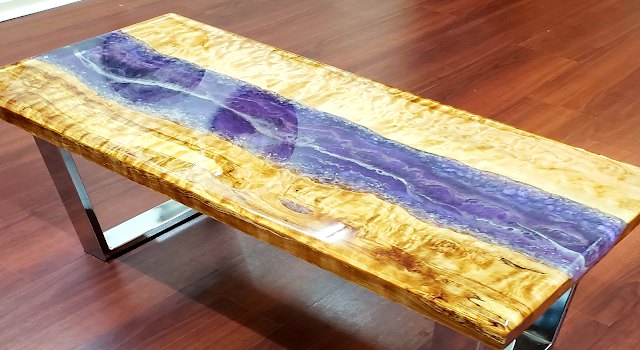

River Table Hacks: 4 Simple Steps for Success

River tables have become immensely popular in the last 2 years.

TOOLS & MATERIALS

|

| Extech moisture meter |

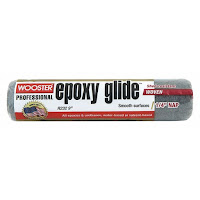

Solvent-safe foam roller

Chip brush

Spray bottle

91% Isopropyl alcohol

Clean, lint-free cloth

Heat gun

DRY

All wood substrates (surfaces) must be completely dry before adding epoxy resin. Kiln dried wood is best for epoxy application. This will also prevent the wood from absorbing moisture from a humid environment. For naturally dried wood, the moisture level should be 12% or lower. Use a moisture meter to get an accurate reading.

Trapped moisture will eventually expand and cause your epoxy to bubble up from underneath. Combined with heat, it will soften and the bond between the wood and resin will fail. The bottom line is never put epoxy resin on wood that has not been properly dried to 12% or below

CLEAN

For best results, you should apply resin on a squeaky clean surface, free from dust, debris and oils. Oils are deposited on the surface from your skin. (Every time you touch the wood, your fingers leave an oily residue behind). Depending on the type of wood you have chosen to use, the steps to achieving a clean surface will vary.

If you have chosen a cradled birch wood panel, it should be sanded and "ready-to-use". All you need to do is spray the entire surface with 91% isopropyl alcohol and wipe clean with a soft, lint-free cloth.

If you are using a live edge slab, you will most likely have a lot of work to do before you are ready to clean. Use a air hose to clear all the dust off of the wood. Using 91% isopropyl alcohol, spray and wipe clean with a lint-free cloth. Repeat until the surface is completely clean. (Denatured alcohol works too)

SEAL

All epoxy resins should be applied in two coats: a SEAL COAT and a FLOOD COAT. Applying a thin coat of epoxy, with a solvent-safe foam roller or chip brush, to the entire area that will be covered with resin. Here are four reasons to seal:- Sealing prevents outgassing of air bubbles into the flood coat of epoxy.

- Sealing prevents color bleeding. Thirsty wood will soak up epoxy, changing the appearance of the wood and any color used will "bleed" into the wood.

- Sealing adheres objects or debris into place and prevents contamination of the flood coat.

- Sealing will make your mold or form watertight and eliminate any possible leaks when pouring the flood coat.

Although one seal coat may be sufficient, a second seal coat may be needed. You should have a glossy finish across the entire wood surface after your seal coat(s) dries.

Do not worry about air bubbles in the seal coat. Just apply and let dry! Your flood coat will cover imperfections. You do not need to sand between coats, as long as you apply the next coat within 72 hours. I do suggest cleaning the area with alcohol between coats.

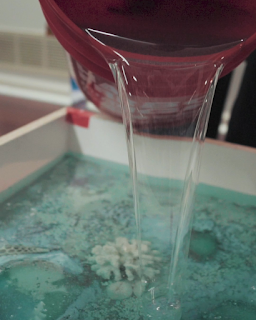

FLOOD

This is the main layer of epoxy resin for your project. It is applied generously and thoroughly to the entire area at once. This thick layer will "self-level" and produce the perfect glass-like finish of epoxy resin. Always read and follow the manufacturer's directions, as every kind of epoxy resin is different in several ways.

Depending on the type of application, more than one flood coat may be required. Some casting epoxies are limited to an inch deep, while others should not be poured more than 2 inches deep.

FINISH COAT

An optional clear top coat of epoxy is recommended when you want the professional finish. A clear coat adds depth and dimension while it amplifies the contrast of colors in the flood coat. This top coat should be a standard epoxy (not casting) which is more viscous, self-levels to 1/8 inch, cures faster and to a harder, more durable finish. This same resin makes for a better seal coat as well. This coat should be poured on and allowed to self-level. If it is necessary to "spread" this coat, use a notched trowel spreader to assure the right thickness.AVOIDING & REMOVING AIR BUBBLES

Air bubbles are normal, in small amounts, and often present in liquid epoxy resin after mixing the correct amount of Part A & Part B. Let's look at what causes air bubbles- Temperature, moisture, excessive whipping, outgassing from the substrate, surface and/or embedded objects- all of which are avoidable.- Epoxy (Part A and Part B) should be acclimated to room temperature before using, as well as your wood. Room temperature should be 70 -78°F. (74° ideal).

- Water is kryptonite to liquid epoxy resin! It will ruin your epoxy mixture and project. A dehumidifier is a great idea. Moisture contamination can come from unexpected sources. ex: Humidity level, sweat, condensation from air conditioner, damp wood, wet paint, adding water-based pigment (food coloring, water color, tempura paint, etc...) utensils, buckets, mixing cups or anything with a drop of water

- When mixing, hand mixing is best. Keep your mixing stick on the bottom of the cup to prevent whipping air into the mixture and scrape the sides, bottom and stick repeatedly during the mixing process. If you do have some bubbles after mixing, let the bucket/cup sit for 30 seconds and use a heat gun to zap the layer of bubbles off the top before pouring. Also, add the epoxy mixture one third at a time using a heat gun to remove bubbles from each layer

- For general de-gassing, I strongly recommend a heat gun, held 4-6 inches above the epoxy resin, continuously moving in a sweeping motion across the whole area. You can repeat this after 30 minutes if needed.

- Outgassing was covered in the seal coat section. This applies to any and all objects that will be covered with resin. (rocks, pebbles, shells, coins, photos, dried flowers, etc...

Choosing a low viscosity epoxy is essential for the flood coat. If you follow the steps outlined here, you won't have a problem with air bubbles. Try using a high viscosity epoxy for sealing and/or top coating for better coverage and faster curing.

CHOOSING THE RIGHT EPOXY

Every brand manufactures multiple resins, each is made for a specific application. In addition, there are many types of resin, again, each one designed for a different use. Be sure you select an epoxy resin made for your type of project. The wrong epoxy will not work!

If you are making a river table (pouring a layer 1/2 inch or deeper) you MUST use a casting resin. These are made to pour deeper than 1/4 inch and are strongly suggested. (recommended depth will vary greatly, read the directions). Deep casting resins are formulated for a slow exothermic process. This is essential to prevent the epoxy from overheating during its exothermic process. On the contrary, epoxy resin must reach the peak exotherm temperature to cure to its full strength. Therefore, using fans to "cool" curing resin is a bad idea.

There are several brands of casting epoxies available. Each is designed for different uses/applications. Casting jewelry, turning blanks and pouring river tables are very different applications! Also, it's important to take into consideration the total volume (mass) you will pour. Exceeding recommended volumes is very risky.

Regardless which epoxy resin you decide to buy, please read ALL manufacturers directions before using. Know the minimum and maximum depth that can be poured, as well as, total volume.

I highly recommend FlowCast by EcoPoxy

What paper do you use to stop the wood sticking to the frame?

This post was such an eye-opener for me, I had no idea about some of the things you mentioned. Thank you for educating me.

Our Website: https://concrete-everything.com/

Was needing tips on how to sand and finish my table top from the point after I pour my epoxy into my river rock table what’s the steps for sanding and finishing? Thank u

Hello,

I am wondering about trying to use latex paint to seal the edges. The paint and the deep pour would be the same color.Do you have any thoughts about this?

Also, does waiting 24 to 72 hours after applying a presumably clear coat of epoxy to edges and surfaces before pouring dyed epoxy work with most deep pour epoxy? Can I just use the same deep pour epoxy, undyed to do this seal coat? I am particularly concerned about colour bleed.